Aluminum has become an indispensable material in various industries, known for its versatility, lightweight properties, and resistance to corrosion. Among the many methods used to shape this remarkable metal, extrusion techniques have stood out as particularly transformative. This article delves into the evolution of aluminum extrusion techniques and their significant impact on modern manufacturing and design.

The Basics of Aluminum Extrusion

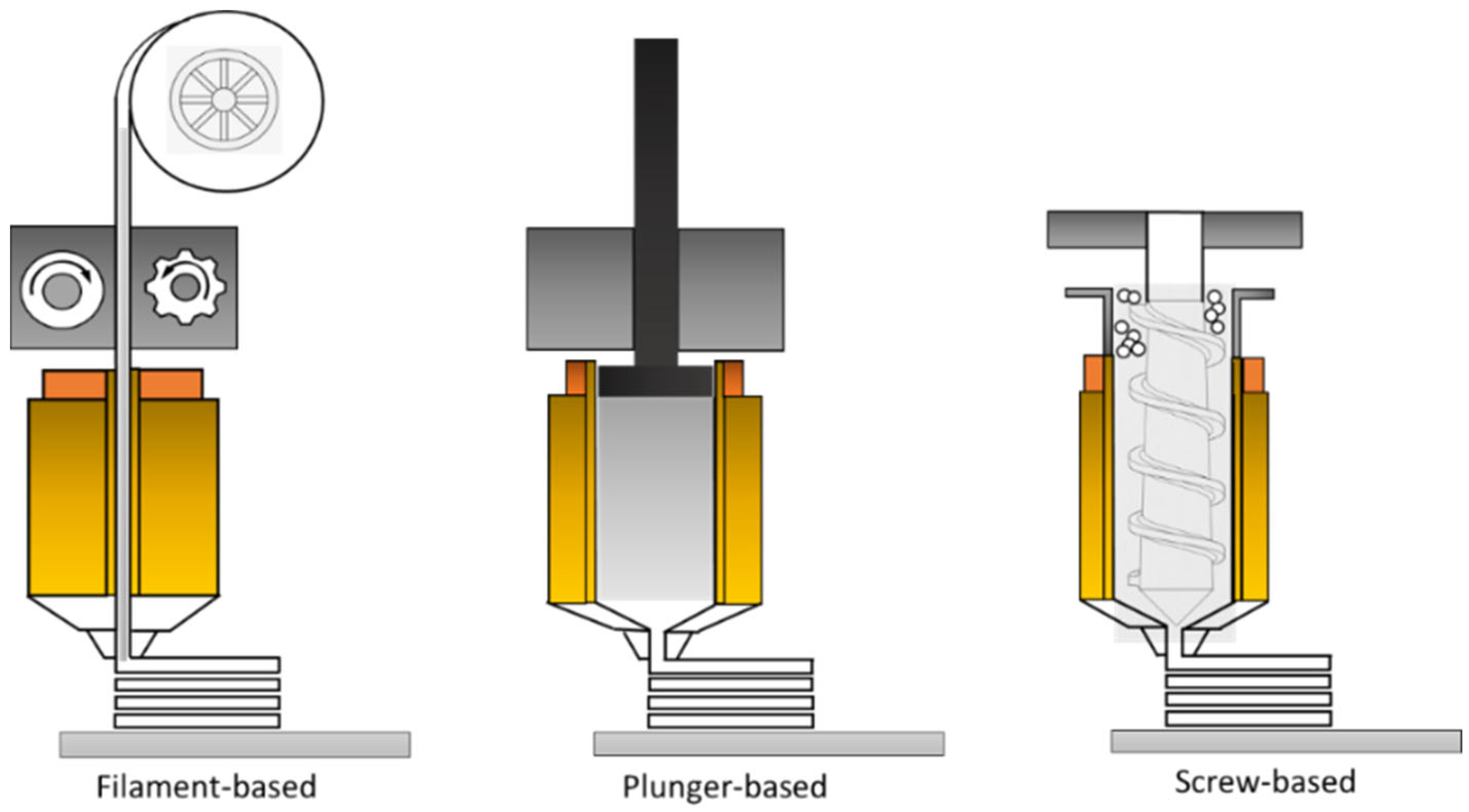

Aluminum extrusion is a process that involves forcing a billet of aluminum through a die to create objects of a fixed cross-sectional profile. This method is analogous to squeezing toothpaste out of a tube, where the shape of the tube’s opening dictates the shape of the toothpaste. The extrusion process enables the creation of complex shapes with high precision and efficiency, making it a popular choice in industries ranging from construction to automotive manufacturing.

The Evolution of Extrusion Techniques

The origins of metal extrusion can be traced back to the early 19th century, with the first patented process being developed by Joseph Bramah in 1797. However, it wasn’t until the mid-20th century that aluminum extrusion techniques began to gain widespread traction. The introduction of powerful hydraulic presses, advanced die materials, and improved heating methods allowed for greater control over the extrusion process, enabling the production of more intricate and consistent profiles.

As technology advanced, so did the capabilities of aluminum extrusion. Modern extrusion techniques have been refined to include precision cooling, automated die changes, and computer-aided design (CAD) integration. These innovations have drastically reduced production times while increasing the complexity of the profiles that can be produced. Today, Aluminum Extrusion components can be found in everything from skyscrapers to consumer electronics, highlighting the material’s versatility.

The Impact on Manufacturing and Design

Aluminum extrusion has had a profound impact on manufacturing, offering numerous advantages that have reshaped product design and engineering. One of the key benefits is the ability to create lightweight yet strong components, which has been particularly beneficial in the automotive and aerospace industries. By using extruded aluminum parts, manufacturers can reduce the overall weight of vehicles and aircraft, leading to improved fuel efficiency and reduced emissions.

In addition to its strength-to-weight ratio, aluminum extrusion allows for the creation of complex shapes that would be difficult or impossible to achieve with other manufacturing methods. This has opened up new possibilities in architectural design, where extruded aluminum profiles are used to create intricate facades, window frames, and structural supports. The flexibility of the extrusion process also enables designers to experiment with new forms and functionalities, pushing the boundaries of what is possible in product design.

Environmental and Economic Benefits

The environmental benefits of aluminum extrusion cannot be overstated. Aluminum is highly recyclable, and the extrusion process itself is relatively energy-efficient compared to other metal-forming techniques. The ability to produce custom profiles with minimal material waste further enhances the sustainability of aluminum extrusion. As industries continue to prioritize sustainability, the demand for extruded aluminum components is expected to grow.

From an economic standpoint, aluminum extrusion offers cost savings through reduced material waste, faster production times, and the ability to produce large quantities of consistent parts. These factors contribute to the widespread adoption of aluminum extrusion in various industries, making it a cornerstone of modern manufacturing.